CASE STUDY

In addition to Alderley Park, we were asked to support Sodexo in keeping its customers well-nourished at AstraZeneca’s second largest manufacturing site and European centre for packing.

AstraZeneca in Macclesfield pushes the boundaries of science to deliver life-changing medicines.

With a focus on the research and development of science-led solutions to diseases, it’s here that the team manufactures, packs and distributes medicines to 130 global markets.

The Challenge

Faced with feeding out-of-hours production staff, working round the clock in the fight against cancer, cardiovascular and respiratory diseases, Sodexo needed to get nutritious meals to the evening shift without any compromise on quality.

Due to pandemic-related restrictions, this also needed to be done in a safe manner, reducing the volume of people mixing across various buildings and visiting restaurants across campus.

Our Seamless Solution

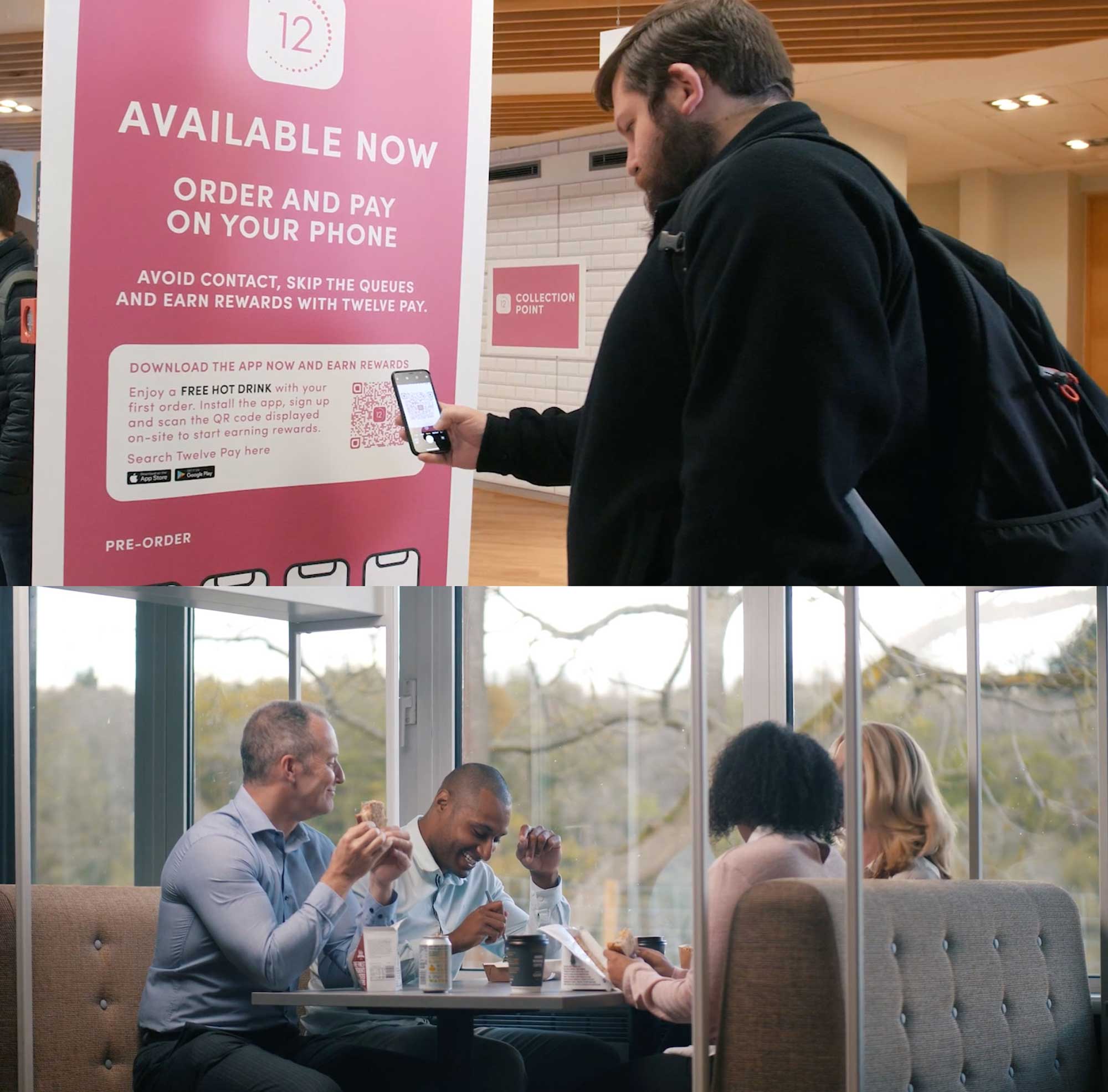

Working closely with Sodexo’s leadership team and the chefs on site, we recommended our multi-temperature pods, accessed via the existing app and located in an easily accessible area.

The ordering/delivery process couldn’t be simpler for both the customer and catering team:

- A customer orders on the app, selects the time they’d like to collect

- The kitchen instantly receives the order with a full list of allergen information

- When the kitchen delivers the order, a confirmation is sent to the customer, and they simply collect from an allocated pod via a QR code/access button on their smart phone, any time it suits them.

Our 24/7 support team also provided software integration with the existing kitchen dashboard, specific menu selections, HSE compliance, and full, ongoing product training – on and off site.

The Results

The pods provided a pandemic-proof solution for offering fresh, nutritious meals to the on-site workforce, both during the day, and into the night.

Because the temperature of each individual pod can be set to provide the perfect environment for the food inside – whether hot, ambient or cold – there’s no time limit on how long it can be held before collection. This makes it particularly ideal for out-of-hours workers.

The chef prepares and delivers the last meal at 5pm, and it’s then held at the perfect temperature and texture until the customer collects it 3 hours later.

Beyond the pandemic, as the world gradually reopens, the longer-term benefits continue to be plentiful. The kitchen can provide:

- Catering for out-of-hours and night-shift workers

- Food at a time suited to individual employees’ work pattens

- Safe, contactless food service

- Hot and cold meals outside of the restaurant’s opening hours

- Nutritional meals with clear calorie and allergen information

- Reduced wastage and refined supplier deliveries, as everything is pre-ordered

- An eradicated need for queuing

- Reduced cash handling with contactless payments taken through the app.